Lynx® ST Connectors

Enables integration of steamable hard piped process equipment with disposable sterile fluid paths

Less<<

Related Resources

Recommended Products

Overview

The Lynx ST (Steam-To) connector provides a reliable and validated connection for the transfer of sterile fluids. One of many Mobius® single-use bioprocessing solutions, it is designed to connect steamable hard-piped processing systems to sterilized disposable flow paths. The Lynx ST connector is available in a wide range of sizes and configurations, from sampling to intermediate additions to bulk liquid transfer into and out of the bioreactor.

Unlike standard aseptic connections where system sterility is operator- and procedure-dependent, the gamma sterilized ready-to-use disposable assembly with Lynx ST connector assures sterility of the overall system.

Safe, Disposable Connectors

The Lynx ST connector is disposable and intended for single-use in transfer and sampling applications. With the Lynx ST connector, there are no parts to clean-in-place, improper sterilization is no longer a setback and the risk of cross-contamination is eliminated.

Quick and Easy Connectivity

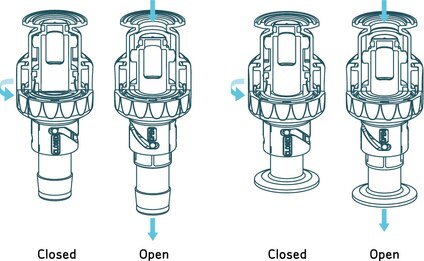

Standard TC fittings connect the disposable fluid path assembly to your piping. Once in place, a quick twist of the Lynx ST connector starts the flow of your process fluid.

A Range of Configurations

Available in three sizes and four configurations, the 1/4-inch, 1/2-inch and 1-inch Lynx ST Connectors can be adapted to a wide range of disposable fluid assembly paths.

Benefits

- Eliminates the risk associated with aseptic connections

- Economical, fast, and easy connectivity for maximum flexibility

- Single use eliminates risk of cross-contamination

- Validatable, sterile connections

A Validated Alternative to Aseptic Connections

Connecting to stainless steel tanks, piping and other fixed process equipment is easy, secure and can be validated. Applications include, but are not limited to:

- Product sampling from tanks or process piping

- Small to large volume fluid transfer or intermediate additions

- Direct connection to high-flow fluid filters eliminating the use of expensive stainless steel valves

Solid, Streamlined Design

Constructed of high temperature resistant polyetherimide (PEI) and silicone seals, the Lynx ST connector provides the reliability and strength you require. Three silicone seals ensure and maintain the flow path sterility for the 1/4-inch, 1/2-inch and 1-inch Lynx ST connectors.

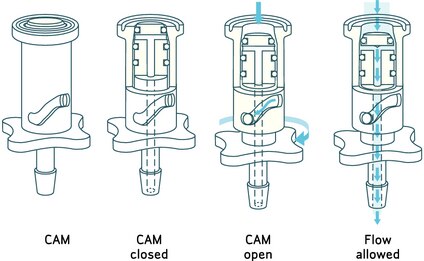

The front seal closes the flow path and provides the Steam-To connection to the stainless steel process tank or piping. The middle seal secures the liquid flow path from leaks. The third or rear seal isolates the flow path from outside environmental contamination.

Connect, SIP, Run

1. Simply remove your sterilized fluid path assembly from the package.

2. Using the recommended Tri-Clover® gasket and Tri-Clover clamp, connect the closed Lynx connector and associated disposable assembly to the stainless steel tank or process piping.

3. Steam-in-place (SIP) the stainless steel system. The SIP process also sterilizes the Lynx ST connector Tri-Clover clamp interface, ensuring a sterile connection between the disposable fluid path and the stainless steel system.

4. Once the system has been charged with the sterile liquid, simply open the Lynx ST connector to start the flow of process fluids through the disposable fluid path.

5. When the fluid transfer is complete, turn the Lynx ST CAM to the closed position or clamp the tubing off.

And, unlike conventional aseptic connection devices, the Lynx ST connector, with the use of a SIPable tee, can connect multiple, pre-sterilized plastic components together.

Applications

Ideally suited to a broad range of applications including sterile liquid transfer and microbiological sampling, the Lynx ST connector provides the optimum solution for making secure, safe connections from sterilized single use disposable assemblies to stainless steel systems.

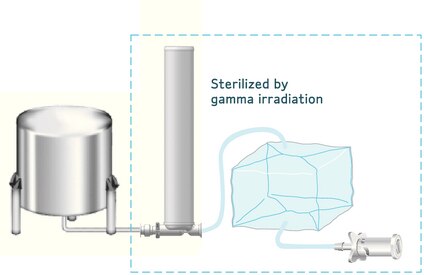

Sterile Liquid Transfer

The Lynx ST connector can be integrated with assemblies that include single-use capsules, tubing, process containers, etc. Sterilized by gamma irradiation and ready to use, these assemblies are ideal for a wide range of liquid transfer applications and are easily integrated into both the bulk production and final fill process, ensuring the secure transfer of your valuable product. Best of all, the entire assembly is disposable.

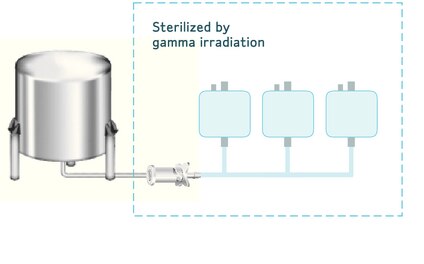

Microbiological Sampling

For large sampling sizes or applications requiring large numbers of samples, such as bioreactor sampling, the Lynx ST connector can provide an efficient and secure connection that reduces the risk of contamination.

A number of flexible sampling containers can be linked to each other via a Lynx ST connector, and the entire assembly can be sterilized by gamma irradiation. This sterile connection to the sample point minimizes the risk of false positives.

The Emprove® Program

The Emprove® Program complements the product portfolio through

- Comprehensive documentation to support qualification, risk assessment and process optimization needs.

- Consolidation of product specific testing, quality and regulatory information to simplify compliance requirements.

- Convenient 24/7 access to up-to-date product information.