NovaSyn® TG resins for solid phase peptide synthesis

High quality resins suitable for continuous flow and batch synthesis – long and challenging sequences

More

High quality resins suitable for continuous flow and batch synthesis – long and challenging sequences Less

More>>

Less<<

Recommended Products

Overview

Specifications

Ordering Information

Documentation

Related Products & Applications

Product Families

SpheriTide™ – the sustainable support for peptide synthesisSpheriTide™ resin is a novel hydrophilic, high-load support for both research and large-scale production of peptides.Learn More >> |

PEGA resinsPEGA resins swell extensively in a wide range of solvents and are ideally suited for the preparation of peptide libraries, affinity purification, and on-resin enzyme assays.Learn More >> |

NovaPEG resinsExcellent support for synthesis of long and difficult peptides. Work synergistically with pseudoproline dipeptides.Learn More >> |

NovaGel™ resins for peptide and organic synthesisNovaGel™ resins for peptide and organic synthesis: High substitution, broad solvent compatibility and excellent swelling properties make it an excellent support for peptide and organic synthesis.Learn More >> |

Related Products By: Brand Facete

| NovaSyn® |

| Novabiochem® |

Categories

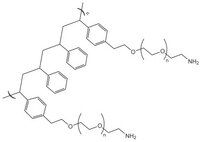

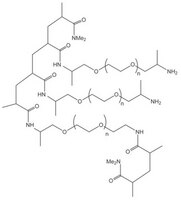

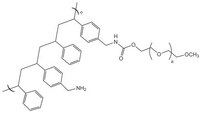

NovaSyn® TG and NovaSyn® TGR resins are based on a composite of low cross-linked hydroxyethylpolystyrene and polyethylene glycol which has been terminally functionalized. NovaSyn® TG resin is available as 90 µm and 130 µm beads. These resins are suitable for both continuous flow and batch peptide synthesis. The NovaSyn® TGR resins have been specifically designed for the synthesis of long and challenging sequences.

They have excellent physical stability in flow systems, are resistant to abrasion and mechanical pressure, and offer improved chemical efficiency. High flow rates have even been reported to increase the acylation and deprotection rates of NovaSyn® TG resins1.

1. a) W. Rapp et al. in “Peptides 1988, Proc. 20st European Peptide Symposium”, G. Jung & E. Bayer (Eds.), Walter de Gruyter, Berlin, 1989, pp. 199; b) W. Rapp, et al. in “Innovation and Perspectives in Solid Phase Synthesis”, R.Epton (Ed.), SPCC (UK) Ltd, Birmingham, 1990, pp. 205; c) L. Zhang et al. in “Peptides 1990, Proc. 21st European Peptide Symposium”, E. Giralt & D. Andreu (Eds), ESCOM, Leiden, 1990, pp. 196; d) E. Bayer (1991) Angew. Chem. Int. Ed. Engl., 30, 113; e) E. Bayer et al. in “Peptides Structure and Function”, V.J. Hubry & D.M. Rich (Eds.), Pierce Chemical Company, Rockford, 1983, pp. 87; f) W. Rapp and E. Bayer in “Polyethyleneglycol chemistry, Biochemical and Biomedical Applications”, J.Milton-Harris (Ed.), Plenum Press, 1992, pp. 325; g) W. Rapp, et al. in “Peptides 1994, Proc. 23rd European Peptide Symposium”, H. Maia (Ed.), ESCOM, Leiden, 1995, pp. 87.